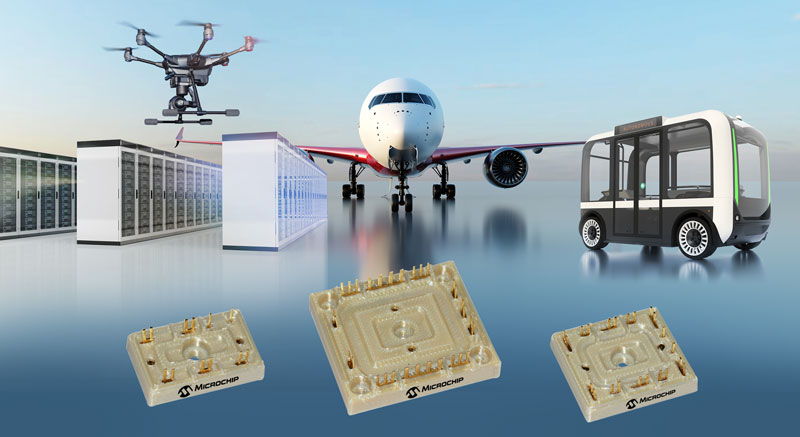

First Aerospace-qualified Baseless Power Module Family Improves Aircraft Electrical System Efficiency

Microchip’s BL1, BL2, and BL3 family, developed with the Clean Sky consortium, is qualified to stringent aerospace standards for AC-to-DC and DC-to-AC power conversion

In the race to reduce aircraft emissions, developers increasingly are moving toward more efficient designs including electrical systems that replace today’s pneumatics and hydraulics powering everything from onboard alternators to actuators and Auxiliary Power Units (APUs). To enable next-generation aircraft electrical systems, new power conversion technology is required. Microchip Technology Inc. (Nasdaq: MCHP) today announced its development with Clean Sky, a joint European Commission (EC) and industry consortium, of the first aerospace-qualified baseless power modules enabling higher-efficiency, lighter, and more compact power conversion and motor drive systems.

Partnering with Clean Sky to support aerospace industry goals set by the EC for stricter emission standards that result in climate-neutral aviation by 2050, Microchip’s BL1, BL2 and BL3 family of baseless power modules provides greater efficiency in AC-to-DC and DC-to-AC power conversion and generation through the integration of its silicon carbide power semiconductor technology. Forty-percent lighter than others due to the modified substrate, the innovative design also produces an approximate 10% cost savings over standard power modules that incorporate metal baseplates. Microchip’s BL1, BL2, and BL3 devices meet all mechanical and environmental compliance guidelines outlined in RTCA DO-160G, the “Environmental Conditions and Test Procedures for Airborne Equipment,” Version G (August 2010). RTCA is the industry consortium that develops consensus on critical aviation modernization issues.

The modules are available in low-profile, low-inductance packaging with power and signal connectors that designers can solder directly on printed circuit boards, helping to speed development and increase reliability. And, the same height between the modules in the family enables them to be paralleled or connected in a three-phase bridge and other topologies to achieve higher-performing power converters and inverters.

”Microchip’s powerful new modules will help to drive innovation in aircraft electrification and, ultimately, progress toward a future of lower emissions,” said Leon Gross, vice president of Microchip’s discrete products business unit. “This is an enabling technology for the systems ushering in a new era of flight.”

The family incorporates silicon carbide MOSFETs and Schottky Barrier Diodes (SBDs) to maximize system efficiency. In packages delivering 100W to more than 10 KW of power, the BL1, BL2, and BL3 family are available in numerous topology options including phase leg, full-bridge, asymmetric bridge, boost, buck, and dual common source. These high-reliability power modules are available in voltage ranges from 600V to 1200V in silicon carbide MOSFETs and IGBTs to 1600V for rectifier diodes.

Microchip’s power module technology as well as its ISO 9000- and AS9100-certified fabrication facilities provide high-quality units through flexible manufacturing alternatives

While introducing innovations the company also teams with system manufacturers and integrators on obsolescence management, supporting customers’ efforts to minimize redesign work and lengthen life cycles, thereby reducing overall system costs.

The company’s baseless power modules complement its aerospace portfolio of motor drive controllers, storage integrated circuits, Field Programmable Gate Arrays (FPGAs), microcontrollers (MCUs), microprocessors (MPUs), timing products, semiconductors, and point-of-load regulators – providing designers with total system solutions for a wide variety of aerospace and defense applications. Microchip also provides a full portfolio of silicon carbide technology solutions for aerospace, automotive, and industrial applications.