Atrenne’s Aluminum 3D Printed ATR Greatly Reduces Lead Time

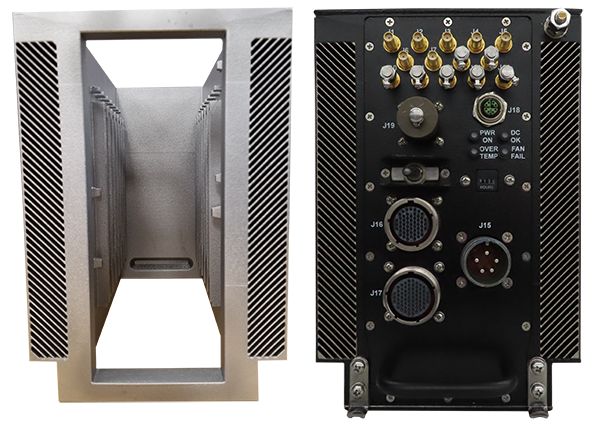

Atrenne Computing Solutions, a Celestica Company, announced it has won a platinum innovators award for design and testing an aluminum 3D-printed air transport rack (ATR) chassis, which is deployable. This enables Atrenne to provide program managers with a ruggedized demonstration unit in a matter of weeks after critical design reviews, compared to months for a conventionally designed unit.

The importance of minimizing lead time is significant for land, sea, and air applications. Early field demonstration units are invaluable to the end-user to allow them to meet critical interim milestones and quickly detect critical integration characteristics with surrounding equipment. The ability to quickly test the unit at the design stage and iterate, if needed, assures a seamless field install and integration.

“Atrenne is raising the bar in both technology and methodology for exceeding extreme environmental demands,” said Jim Tierney, VP of Aerospace and Defense. “Our 3D Aluminum ATR offers substantially reduced lead times when compared to conventional braze welding fabrication, with negligible tradeoffs in thermal performance, and the structural and mechanical characteristics are as good or better when subjected to dynamics testing.”

Atrenne has been designing and manufacturing rugged military systems for the defense industry for nearly 50 years and continues to deliver solutions to the military as quickly as possible through innovative engineering and manufacturing processes.