Using Carbon Fiber Structures for Energy Storage

Carbon fiber has a history dating back to 1870 when it was initially used as a filament for light bulbs. It wasn’t until over a century later that its potential as a lightweight structural material was explored. Recent research from Sweden and England has advanced the concept of multifunctional structural materials using carbon fiber, sometimes referred to as Massless Energy Storage. This concept involves using structural components to store energy, eliminating the parasitic weight of a conventional battery.

The goal is to create a single structural material that stores energy with less weight and improved efficiency compared to current solutions. This innovation has significant advantages over traditional carbon fiber structures combined with conventional lithium batteries. For instance, in electric vehicles (EVs), a 1200-pound battery pack accounts for approximately 25 to 30 percent of the vehicle’s total weight. By integrating the structural composition of the vehicle with energy storage, the vehicle becomes more energy-efficient with an extended range.

The goal is to create a single structural material that stores energy with less weight and improved efficiency compared to current solutions. This innovation has significant advantages over traditional carbon fiber structures combined with conventional lithium batteries. For instance, in electric vehicles (EVs), a 1200-pound battery pack accounts for approximately 25 to 30 percent of the vehicle’s total weight. By integrating the structural composition of the vehicle with energy storage, the vehicle becomes more energy-efficient with an extended range.

The potential impact on military systems, such as VTOLs, aircraft, and drones, is substantial. Reducing the weight of aircraft by minimizing the required batteries has far-reaching implications. Similarly, reducing the weight of battery packs used in communication and wearable solutions offers vast possibilities for various applications.

One area of interest is reducing the cost and weight of wiring harnesses that transport energy between points. Using the vehicle’s entire structure for energy storage could eliminate the need for lengthy wire runs. Another promising area under investigation involves capturing energy from vibrations affecting the structure during normal use, similar to how regenerative braking contributes to energy storage.

The current norm is to build mechanical structures of single purpose materials such as carbon fiber, aluminum, steel etc. In the same manner a battery is considered

a separately unit with “no other” function than energy storage. From a silo perspective, the battery and the structural material performs well at their jobs, but from an efficacy standpoint, the single usage comes at a cost of system volume, weight and overall performance.

The Technology

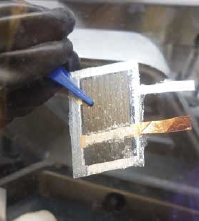

The approach is not to embed a battery within a structural component but to create a unified solution that combines the attributes of carbon fiber and batteries without the weight concerns of traditional batteries. This is achieved by injecting carbon aerogel into the voids of a typical sheet of carbon fiber. Initial tests have shown some negative impacts on the carbon fiber’s strength, but overall results are promising.

While the benchmark of 4.1 kW/kg for conventional battery solutions hasn’t been reached, achieving 1.1 kW/kg with a dualpurpose material is an exciting development. sufficient energy in a commercial aircraft’s wings to power the cabin, or a car’s body panels could store additional energy for increased power needs.

Commercialization

Although storing power in carbon fiber parts has been proven, scaling from limited lab tests to production-level solutions presents challenges. Companies like Volvo and Sinonus are working on bringing such solutions to market, with vehicle body panels showing promise. Questions about environmental impact, heat dissipation, and service cycles are still being addressed.

Adoption Routes

Structural power is still in its early stages, and replacing the average EV battery packs is a long-term goal. However, combining energy storage with the structural needs of a vehicle could provide an auxiliary power source, reducing weight and increasing efficiency. For instance, a military radio’s enclosure could potentially reduce the battery size, contributing to greater SWAP-C efficiency.

The number of charge/discharge cycles a battery can undergo before failure is crucial for EVs and other applications. Although testing is ongoing, the longevity of structural energy storage solutions remains to be fully understood. Currently, replacing batteries in EVs or golf carts can sometimes exceed the vehicle’s value. This concern is still under discussion for structural energy storage applications.

Conclusion

The future battlefield presents numerous energy challenges, and massless energy storage within structures holds great promise. Whether it’s reducing the weight of drones to extend their range or storing energy within bulletproof vests for wearable solutions, this technology is an area to watch closely.